The older models

that have the ATC roll timers on

the front , we left the computer board in. Those do not have the

heater, humidifier and roll relays built on the boards, which give all

the problems.

The newer

models with the roll timer software built in the Watlow controllers, I

took those boards out. To replace I used a cheap 15 volt dc power

supply and 25 amp Normally open, zero switching, solid state

relays for the heater and humidifier circuits. For the high heat limit

I used a 25 amp normally closed, zero switching solid state relay and

loop the hot leg in series with the normally open relay for the heat.

It must be first in line to the incoming power. Editors note: Search eBay for

"solid state relay zero crossing". Expect to pay about $5-$20 USD

On the dc

signal side of the relays, your controllers produce a dc signal to call

for heat or humidifier. You just hook those up straight to the relays

from the controllers. Make sure polarity is correct. Do not tie the

power supply to the signal side of the relay!

For the low

water switch on the humidifiers I used a simple low amp relay( cheap)

that is normally closed. The float valve in the humidifier are closed

when there is water present. So wire the relay so that is opens

the circuit if the humidifier runs out of water. You get your power

from the dc power supply.

For roll

timers I used a ATC

model 422ar. They are panel mount. I installed a normally closed 8

amp push button on the panel for the roll test. The incubators have

terminal strips already in place to tie your hot, neutral and ground to

find power easily. I then used a bistable relay which flips for

clockwise and counterclockwise. Its model number is s90r11abd-120

from TE Connectivity. The wiring is self explanatory with the

instruction from the timer.

For alarms

I used a simple dc powered buzzer and connects directly to the Watlow

controllers relay contacts. The Watlows have a relay built in for each

channel for the alarm circuit. (check your controller model number to

verify)

For the

temp and humid transmitter in the incubator, which sends a signal to

the controller in 4-20ma dc (for all the Hatchrites I have rebuilt). I

used a water proof transmitter from Omega.com Model HX303AC. These are

not cheap but you have to have it for good control. They are $285. They

are the cheapest quality transmitter I can find. What I have

found on the transmitters that Hatchrite used is they get wet and

shorts out the humidifier signal side. Especially the bottom unit on a

stack unit. The cabinet sweats between the outside and inside panels.

Light

circuits just hook up through the switch that is on the panel anyway. I

don�t know why they hooked those up to a relay on the

board. Editors

note: The lights were turned on/off by a timer on the main logic

board on some early units, presumably so that newly hatched chicks

could read books and visit with their friends while waiting to be

rescued from the HatchRite.

I installed

a device on my incubators that is called a iServer model ithx-sd that send me

a text to my cell phone if it goes into alarm.

This is not

the cheapest way to go, but you still have the precise control for the

incubator that will last a long time.

If you want

model numbers for all the parts send me a email back and I will compile

a list.

My motto is

the KISS method. Which means keep it simple stupid.

Jay

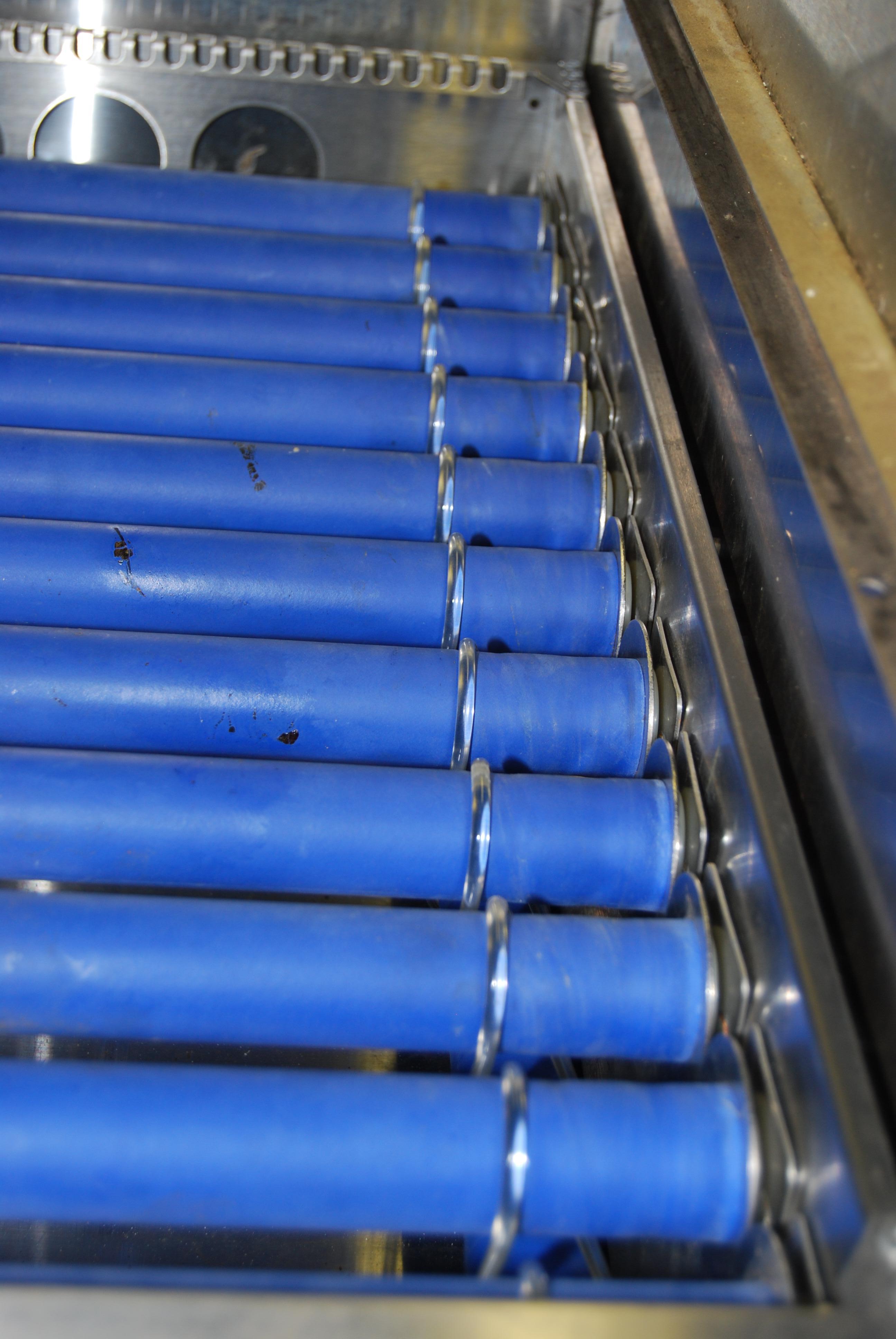

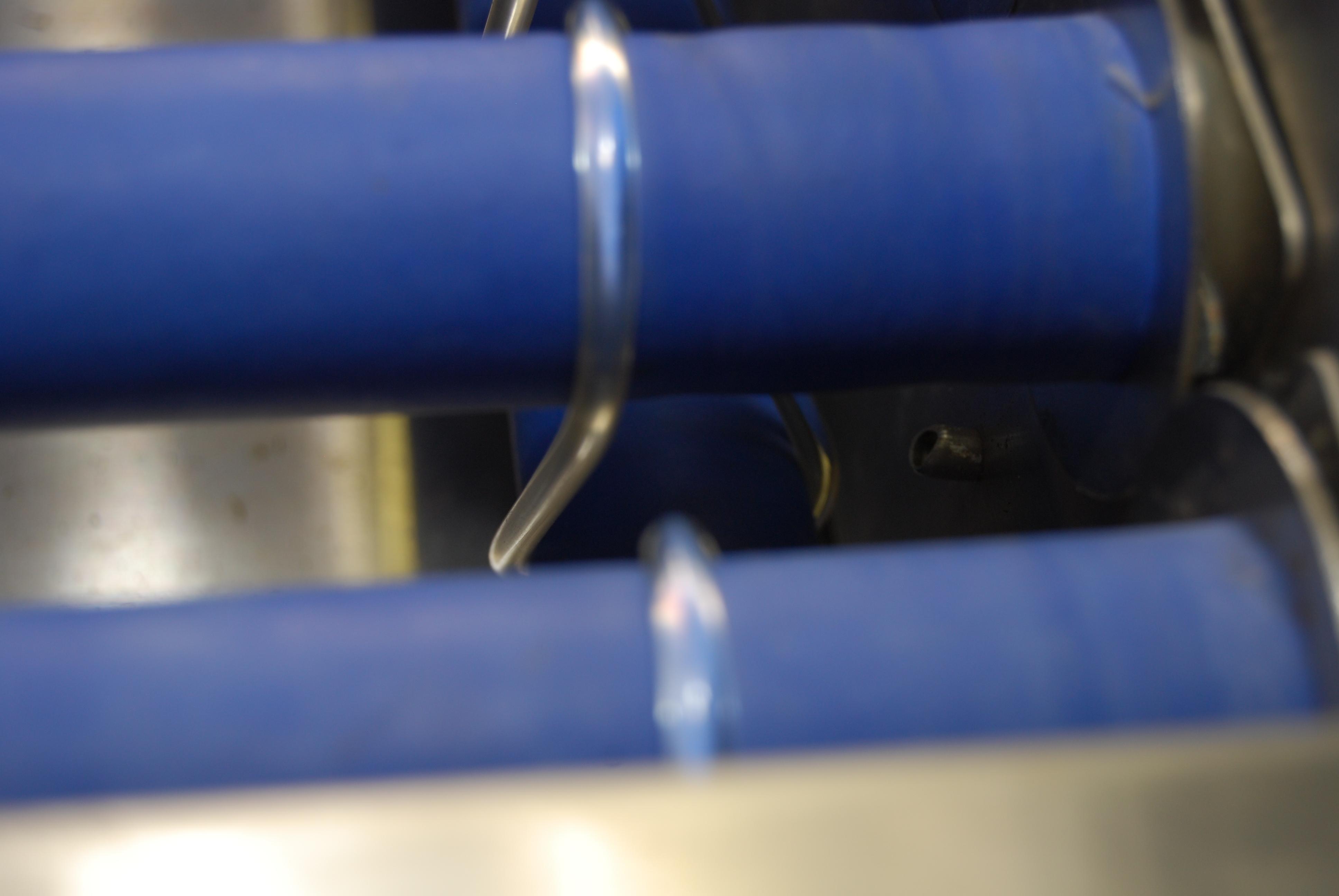

Click the

picture to see a some photos of the

incubator hardware.

Click the

picture to see a some photos of the

incubator hardware.